|

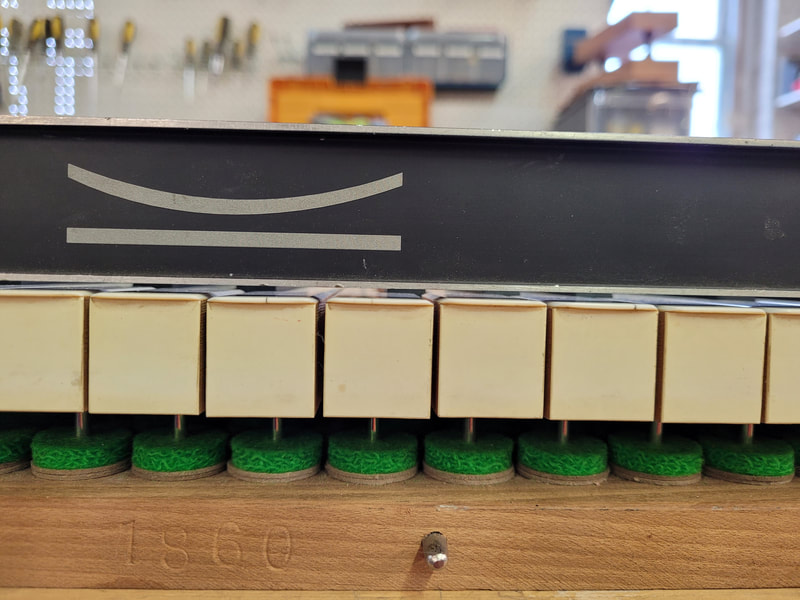

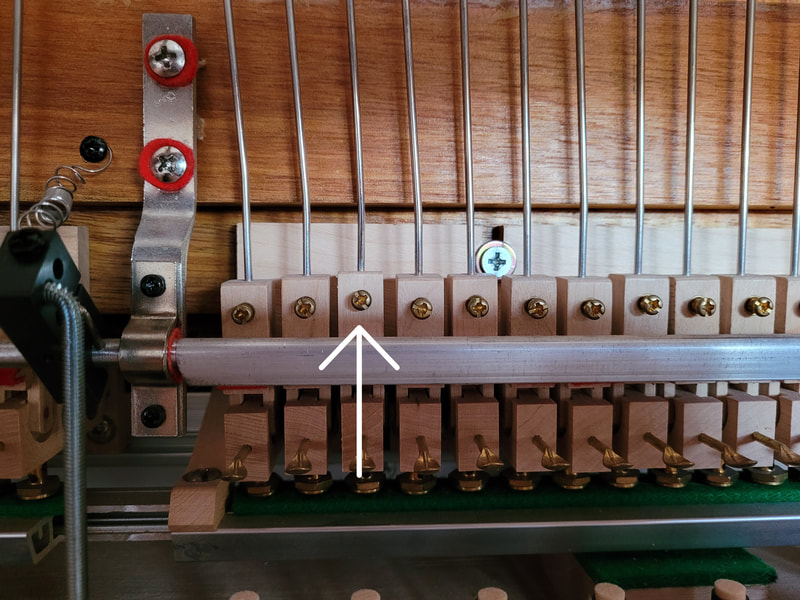

Newly rebuilt piano receiving first round of regulation. Key height adjustment by inserting or removing paper punchings on balance pins. Key dip adjustment by inserting or removing paper punchings on front pins. Adjust Let-off and Drop on jig out side of piano. Backcheck to hammer alignment. Then backcheck height. Repetition spring/wippen spring strength adjustment. Hammer shank traveling, make sure hammers go straight up and down. If bot, shim flange with sticky paper.

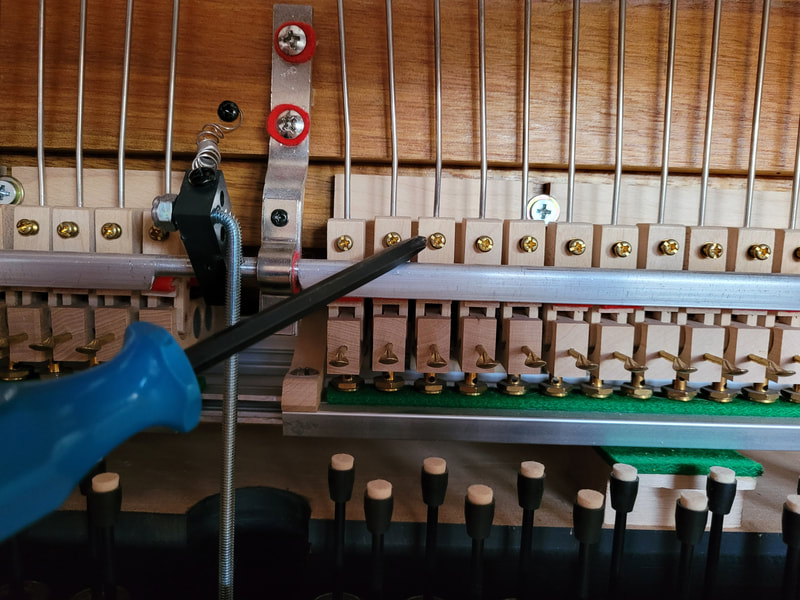

The 3rd damper from left does not lift high enough. When key is fully pressed, a little bit of felt is still touching strings, blocking sound. Look inside the piano, the problem damper post is higher than neighbors. Loosen set screw, lower damper post, tighten screw. The damper works well now. Nice looking action/keyboard!

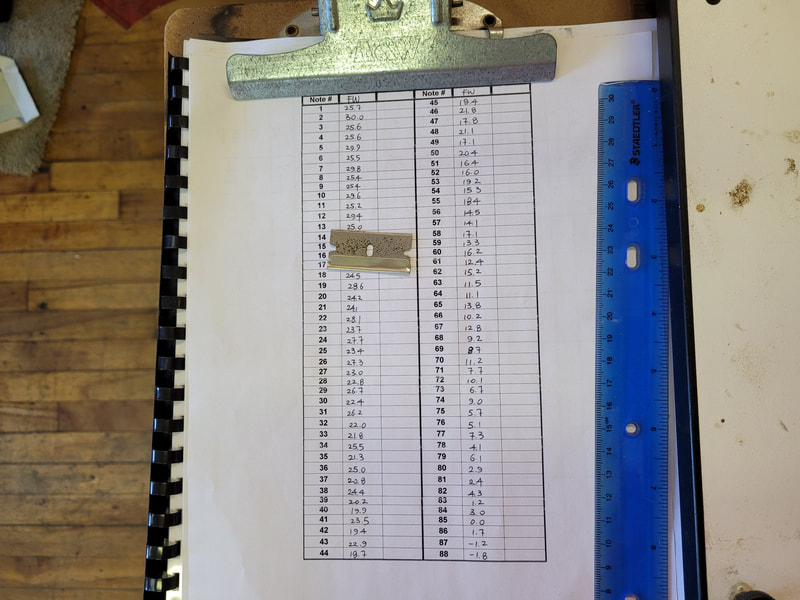

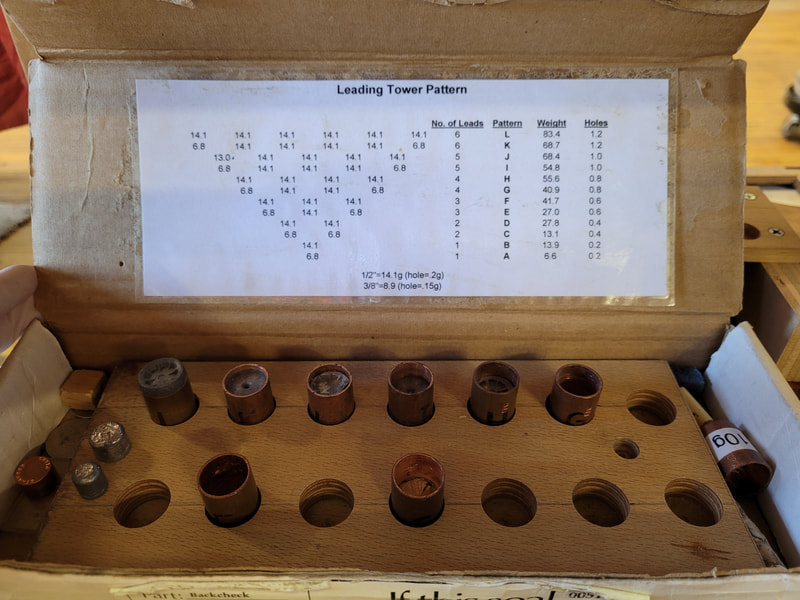

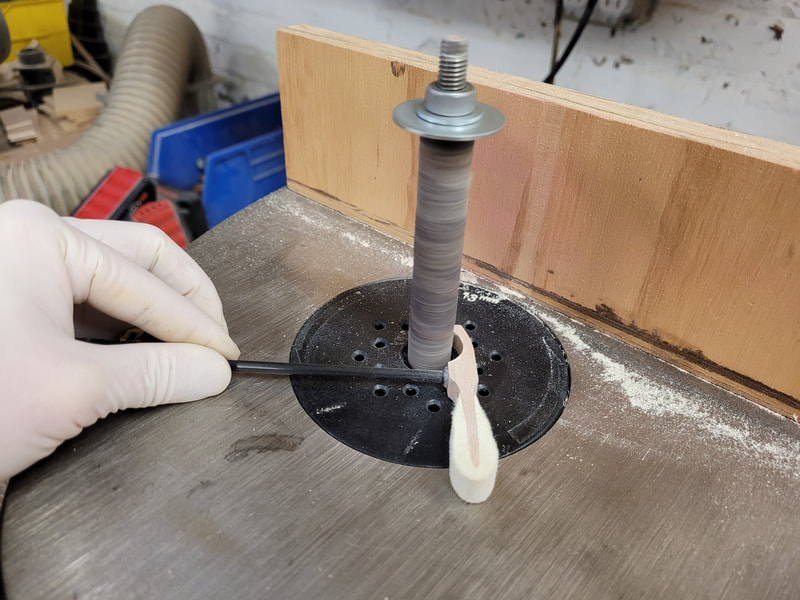

The front weight of keys are calculated, heavy in bass, light in treble. For the weights marked with letters, each letter represents a pattern. Small leads are 6.8 grams each, big leads are 14.1 grams each. I.e. weight "C" represents two 6.8g leads, weight "D" represents two 14.1g leads, "F" represents three 14.1g leads. Pick and move weight on key till the pre-calculated Front Weight (F) is achieved. Use the pattern to mark key lead locations. Drill with forstner bits, 1/2" bit for 14.1g leads, 3/8" bit for 6.8g leads. Put leads in drilled holes and double check front weight. Press leads into keys firmly. After leads are installed, paint sharps with black paint for a uniform look. Let dry over night, then put keys back to key frame for the next steps of adjustments/ regulation.

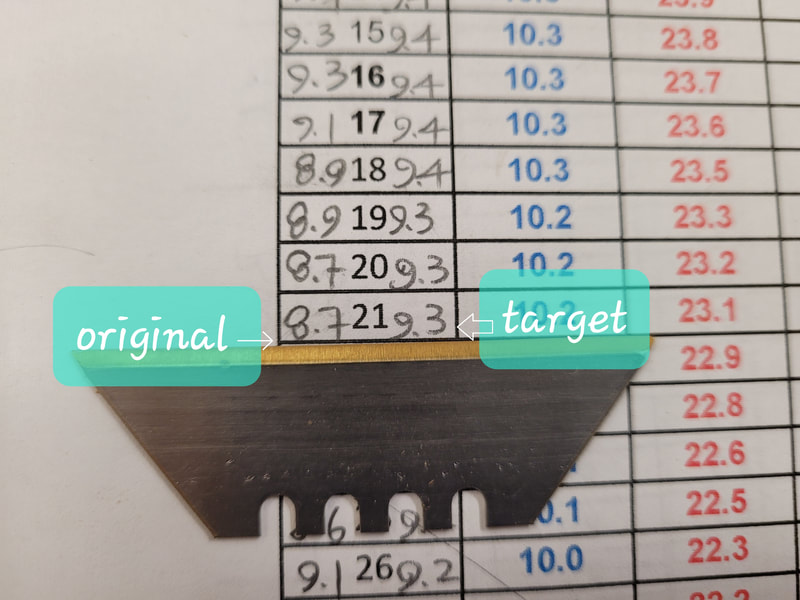

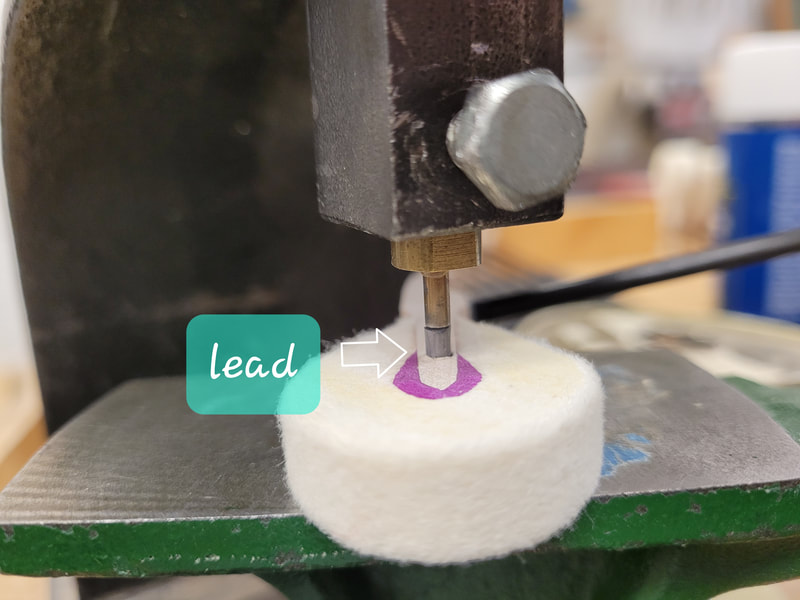

Strike weight (SW) is also hammer weight. It is measured with hammer flange pin resting right on top of bearing. SW is tapered from bass to treble, heavy to light. After measuring the original Strike Weight (SW), and calculation by the shop owner, Mr. Jude Reveley, the SW needs to be adjusted to a even curve by leaving it, adding lead, or sanding material off. To add weight, drill into hammer bolding (the wooden part), cut lead to length, and press lead in. Slight pressure is applied so not to crack the wood. Then measure SW again to double check. To reduce weight, sand some materials off from the molding. The weight calculation enables minimum reduction of weight so the hammer's shape won't be greatly compromised. Double check on scale after sanding.

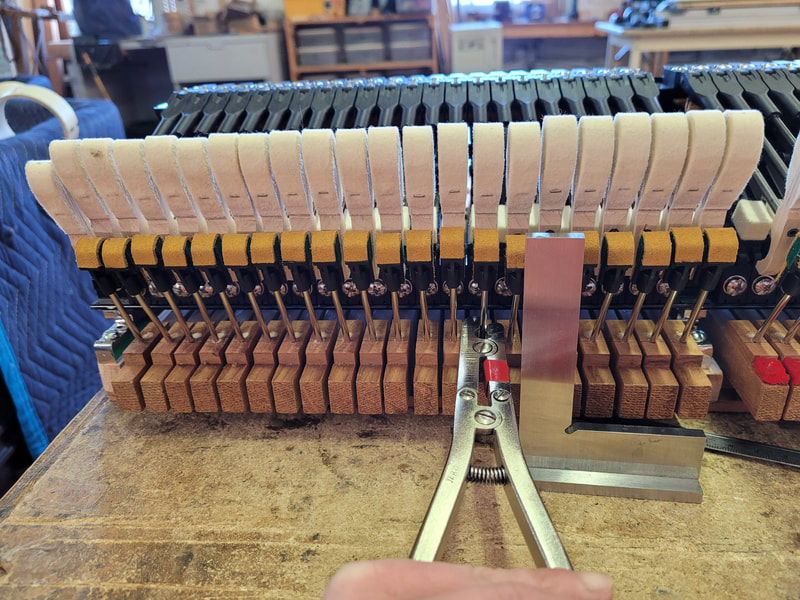

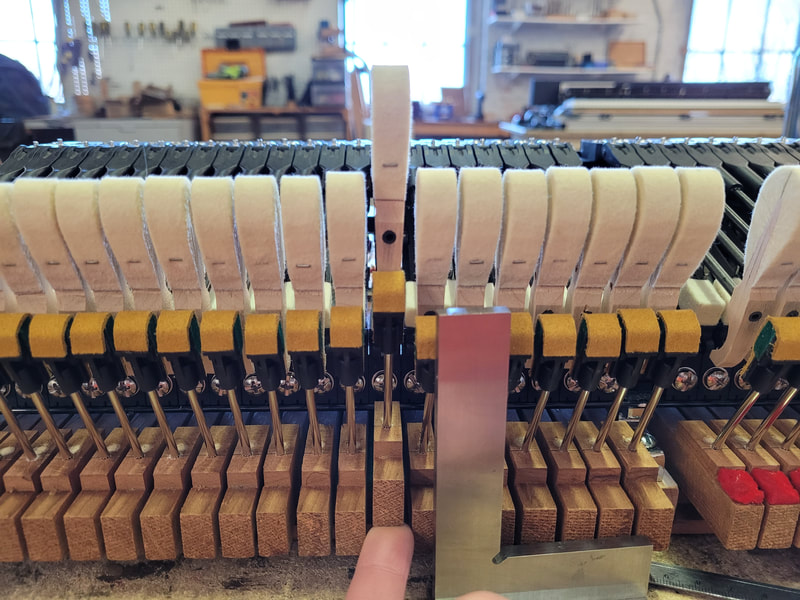

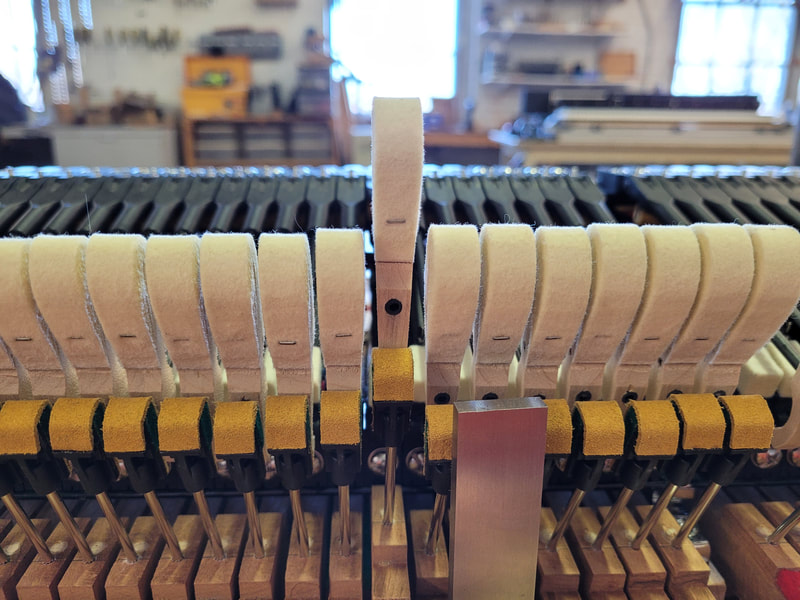

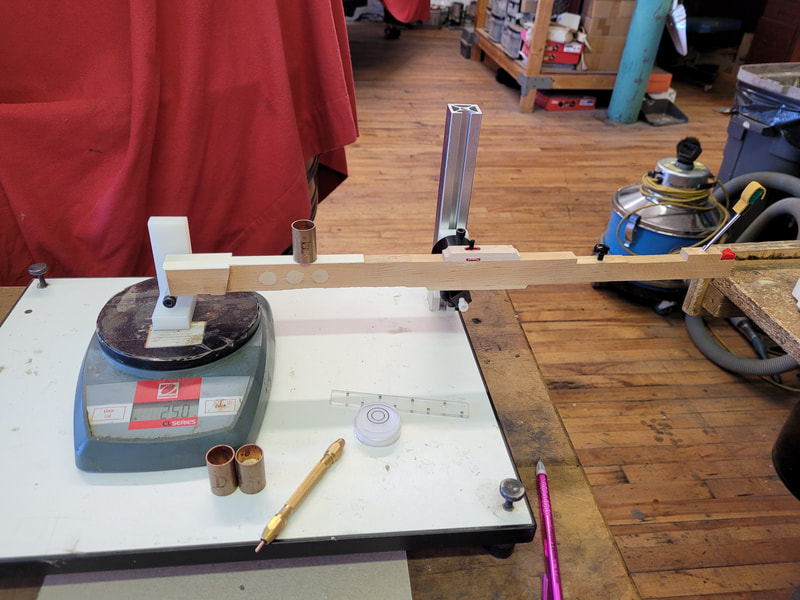

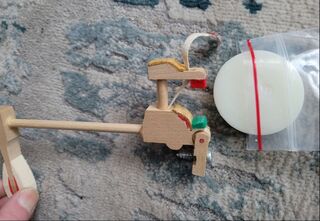

Backcheck position jig, determine where to install backchecks. Mark one sample at treble and one at bass. Connect location from bass sample to treble sample, mark position with a knife, then punch holes. With the holes punched, drill bits will be easier to go in. Drill and install backchecks at 21 degrees. Big Bridgeport made in the 1960s in Connecticut. All backchecks are installed.

In home piano tuning in Billerica, MA. This is a Baldwin vertical piano made in 1994. Piano stays in tune very well. Unfortunately the bass strings sound very dull. They may need to be twisted for one more turn. Didn't try it this time, will talk to the customer to see if she wants to give it a try.  Some hammers are hardened through time. When they strike strings, the sound is very harsh. The needles helped soften the wool on the outside of hammers. The sound is softer after some stabs. Happy with the result.  The yellow colored leather is hardened, making squeaking noise. Ms. Jessica Mass from Interlochen Summer Camp taught me to use ivory soap as lubricant. It worked! The noise disappeared! |

Archives

May 2024

|