|

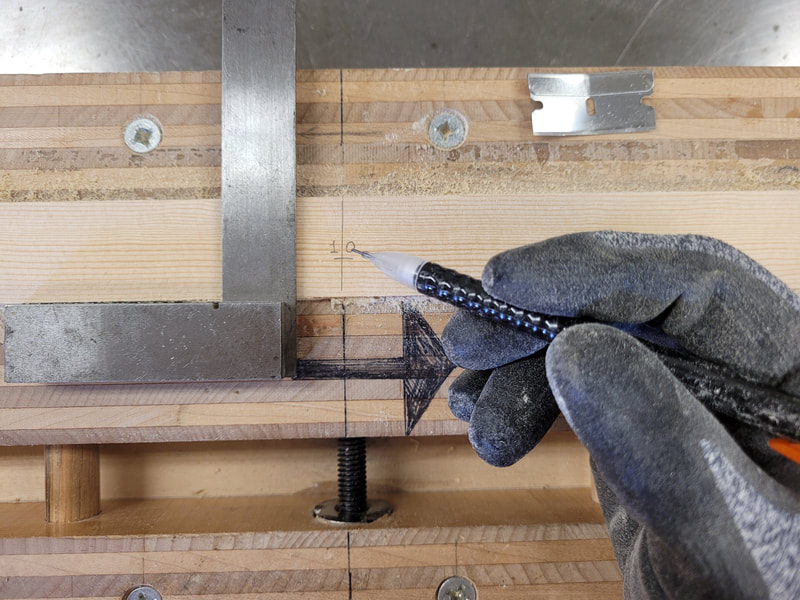

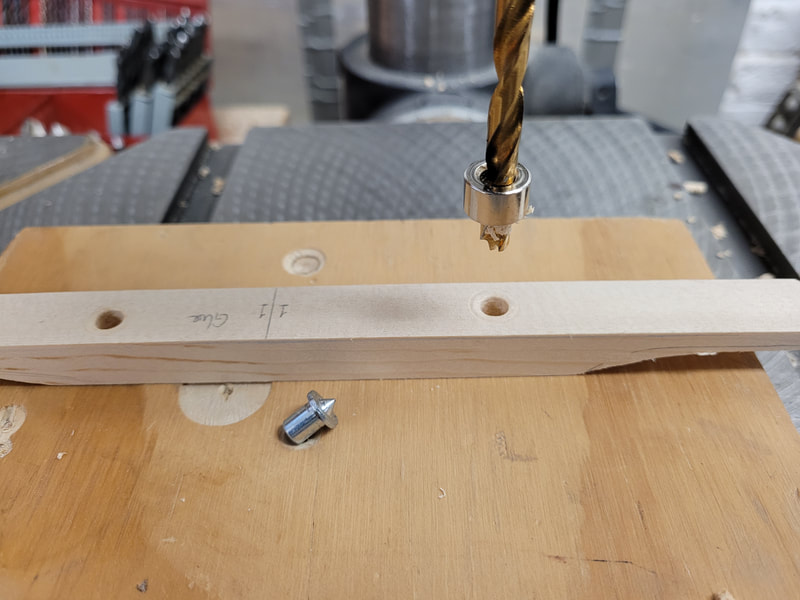

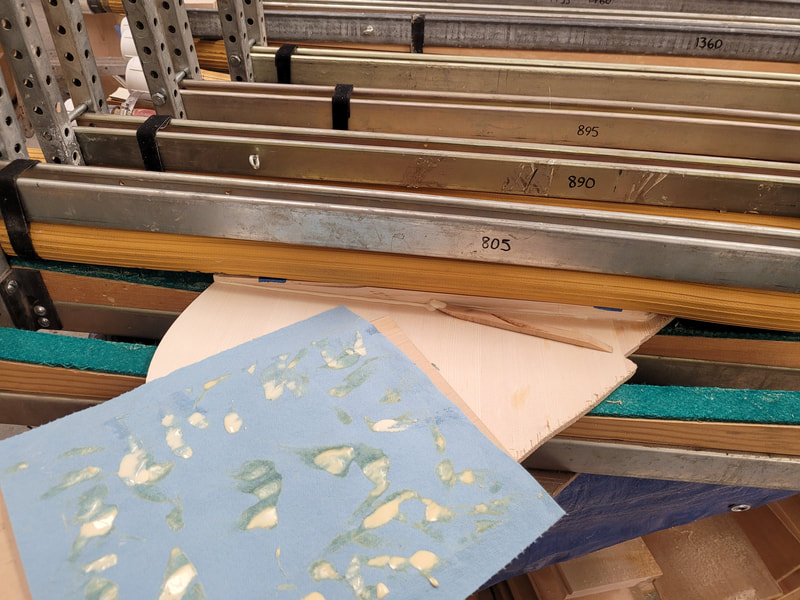

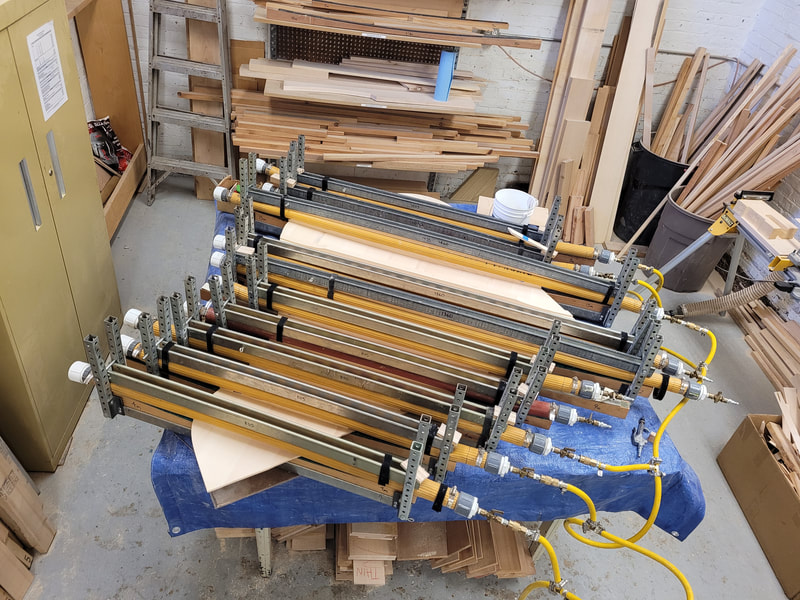

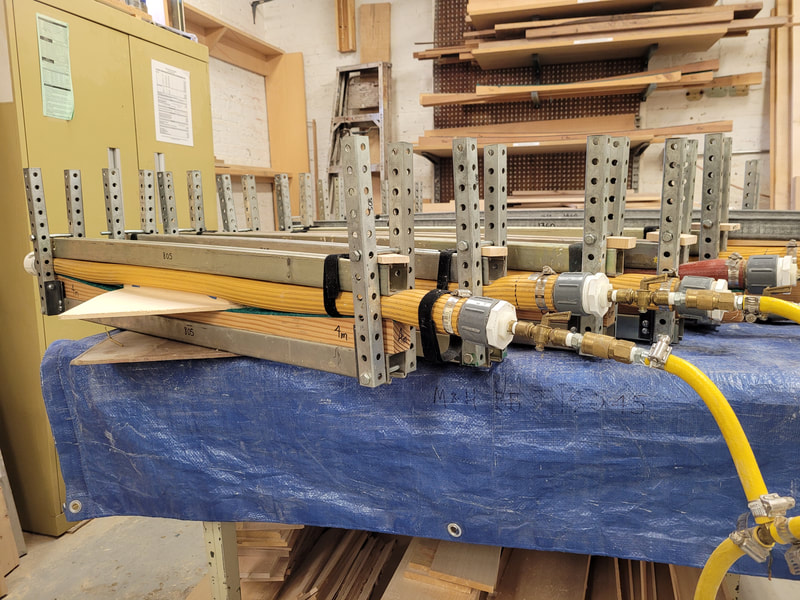

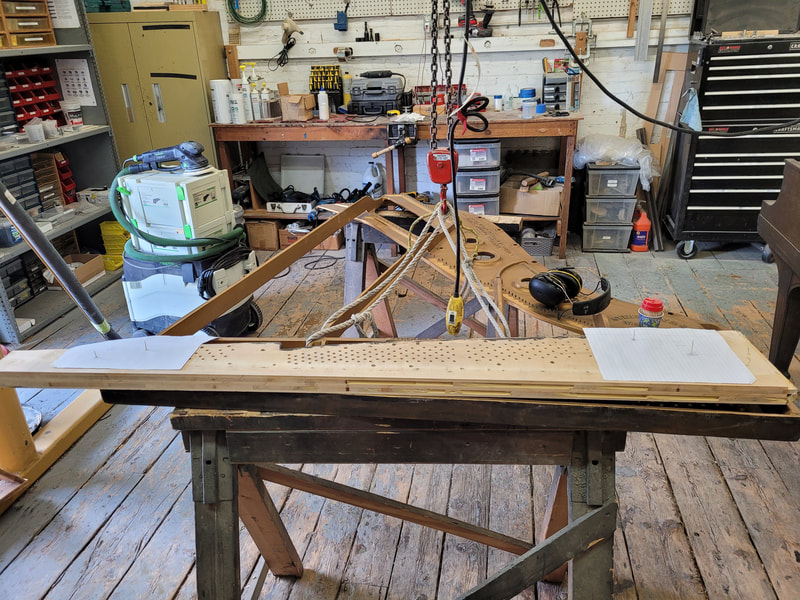

Select wood according to the species, width, and length on the design sheet created by shop owner Jude Reveley. Cut each rib 20cm longer than target length. Place in rib milling jig. Clamp raw rib tightly into jig using caul of target radius. The radius on ribs in one piano at the shop ranges from 4 to 15 meters. The jig is 74 mm thick. Calculate the target rib height and protrusions from jig, give about 2mm room, then saw. Finish rib height by going through plainer. The top side will be the glue surface to soundboard. Scrape a smiling face with razer blade to hold glue. Mark number of rib, release from jig, compare radius with caul. This one looks ok. Trim each rib to target width. Everyone is slightly different. Clean inner rim and rib slots. Place ribs and saw to target length. If ribs wider than original slots, chop and trim slots to fit ribs from the new design. Trace feathers according to the original ribs, saw 2mm+ outside trace line, and fit into piano again. Mark two places for locator dowels on each rib. Use the jig. Drill locator holes with 1/4" bit. Insert locator pins on ribs, place new soundboard in, press down with go bars, press ribs hard on soundboard to transfer pin marks. Release soundboard, check that all rib location marking pins did their job. Remove pins from ribs, insert 1/4" dowels, trim to uniform length. Drill locator holes on soundboard with straight jig, be careful not to drill through the board. Sand the surface with 220 grid sandpaper. Set up air clamps, dry fit each rib before gluing on. Clean glue squeeze outs using a wood stick or something not very sharp. Finish cleaning with a hot wet rag. A thorough cleaning makes sanding much easier later on. We use Titebond 50 for this job. Clamping time is 30 min. With limited amount of clamps, one rib is pressed for more than 30 minutes, then the clamp is moved to glue the neighbor rib. Small shop.

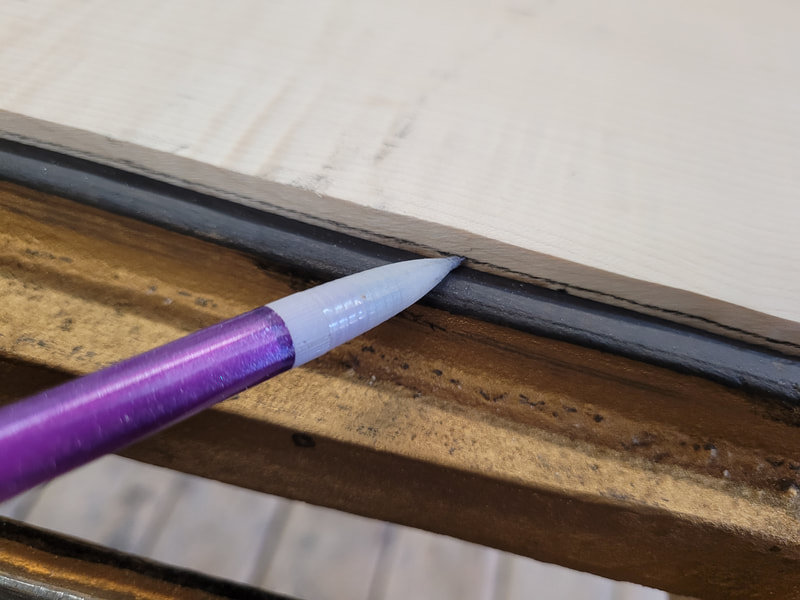

We have some 5 layer maple pinblock (P/B) stock made a while ago. Steinway L P/B is small. So pick a smaller size stock, save the large ones for other pianos. First, trace the bevel side line on to new stock where it butts against plate flange. Adjust bandsaw blade angle to match the old P/B, cut new P/B, skip the divot part. Cut the divot part with a jigsaw, blade angle matching the old block. Check on plate. Brush graphite on plate webbing area, put P/B on, and press/hammer everywhere. At the spot where the plate contacts the P/B, there will be black marks. This is the high spot on new P/B, needs to be sanded off to lower it. Repeat this fit and sand process till marks are everywhere on the P/B. Trace a line where the wood is contacting the plate, mix epoxy with filler till a consistency of mayo, pour under that pencil line, clamp onto plate. Clean up epoxy squeeze out, let dry till the next day. On the next day, sand off excessive epoxy, clamp P/B to plate again to check if there is a gap anywhere. Mark for tuning pins. After drilling for tuing pin holes, mill the new P/B to match the old one When chopping the new P/B for length, leave a little room for it to shift left to right in piano to adjust itself. Double check plate height, then done.

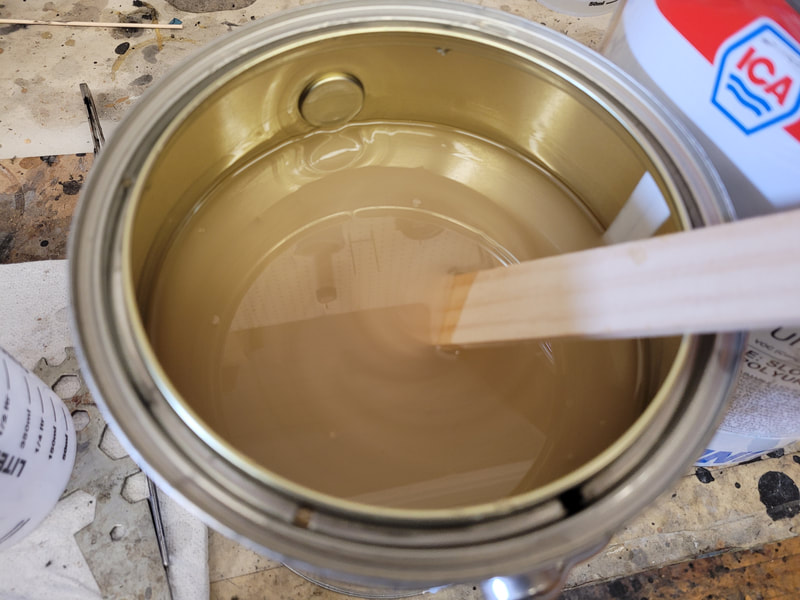

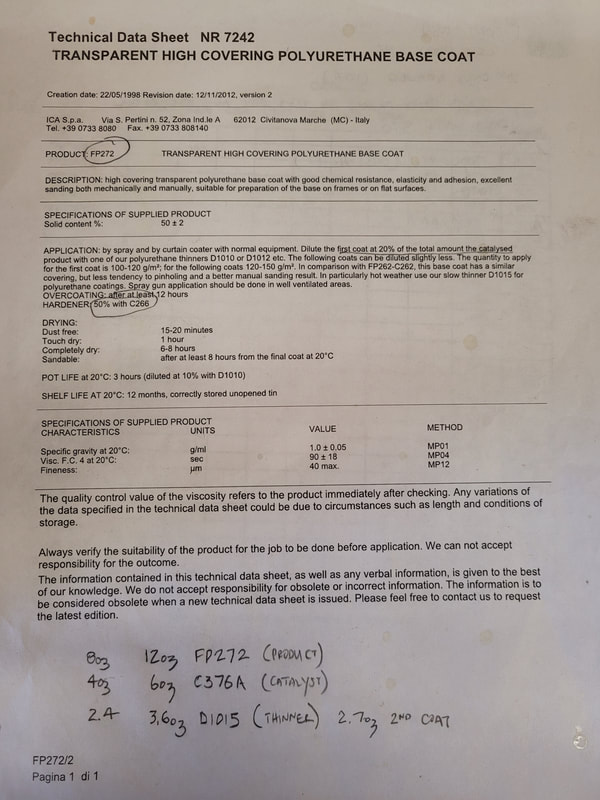

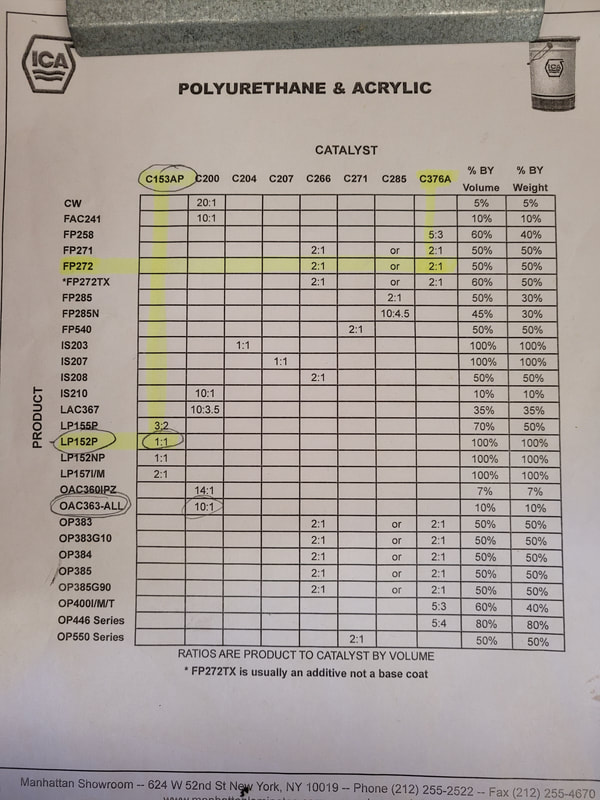

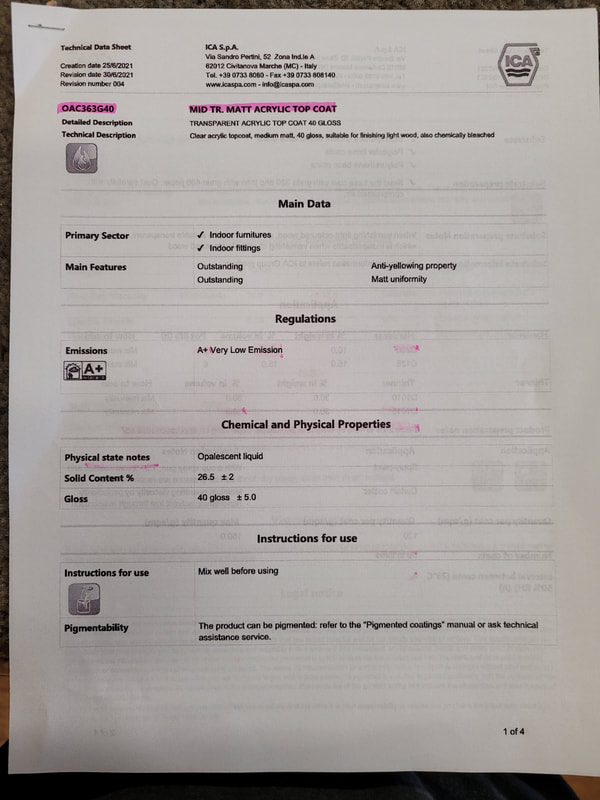

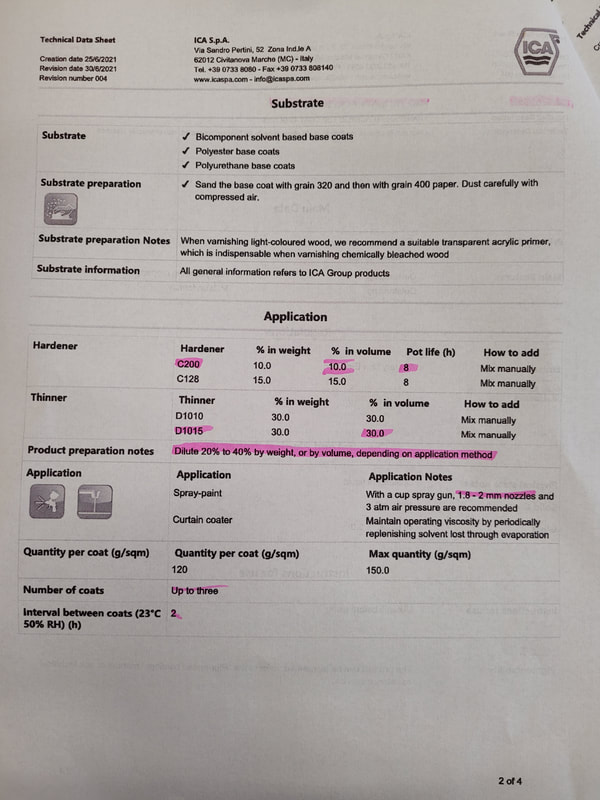

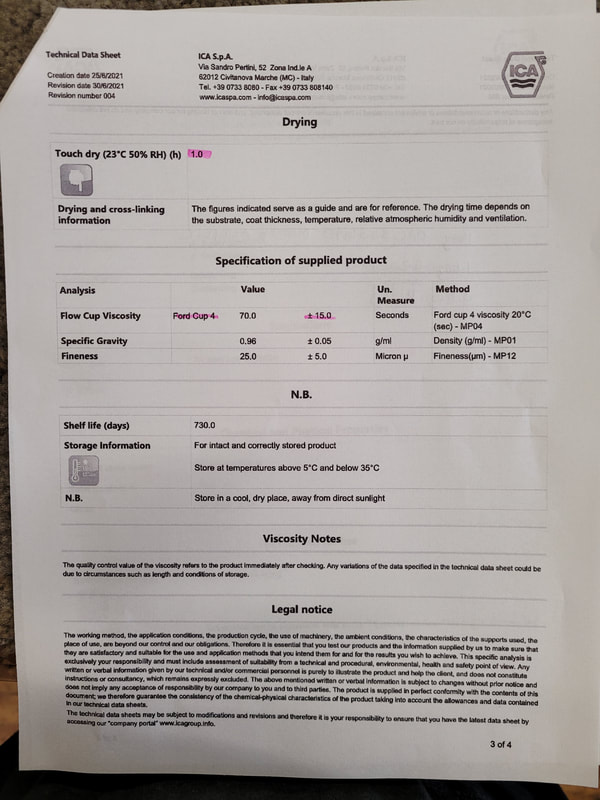

This is at the beginning of spray paint learning curve. My hands were shaking, arms stiff, but recording this anyways. Get to start somewhere. The first step in to spray sanding sealer, 2 coats, 1/2 hour interval. The sealer is made of solid, hardener, and thinner. The D-1015 thinner is for humid weather. D-1010 will be used in dry weather. Before pouring out the solid, stir it well until texture is even, then pour into measurement cup. Shake hardener container to even it up a bit, add hardener to measurement cup, stir thoroughly to combine. The last is to add thinner. Stir all well together. Fill in spray gun container, Adjust fluid and air force, spray evenly. When sealer dries, sand with 320 then 400 grid sand paper followed by scotch bright for a even surface. The top coat here is acrylic, made out of solid, hardener, and thinner again. 2 coats, 2 hour interval between coats. This is after the first coat. No sanding between coats. Instruction for the top coat. 20 oz of solid works just right. Make sure no dust comes in spray booth between coats. Clean gun really well afterwards. A couple hours after the second coat of acrylic, make sure finish is dry, untape the gluing edge, glue the soundboard in piano. Thanks to Ellie's help gluing the big board in. First time spray and glue the board on the same day. Gratitude to our boss and Ellie's support.

|

Archives

May 2024

|