|

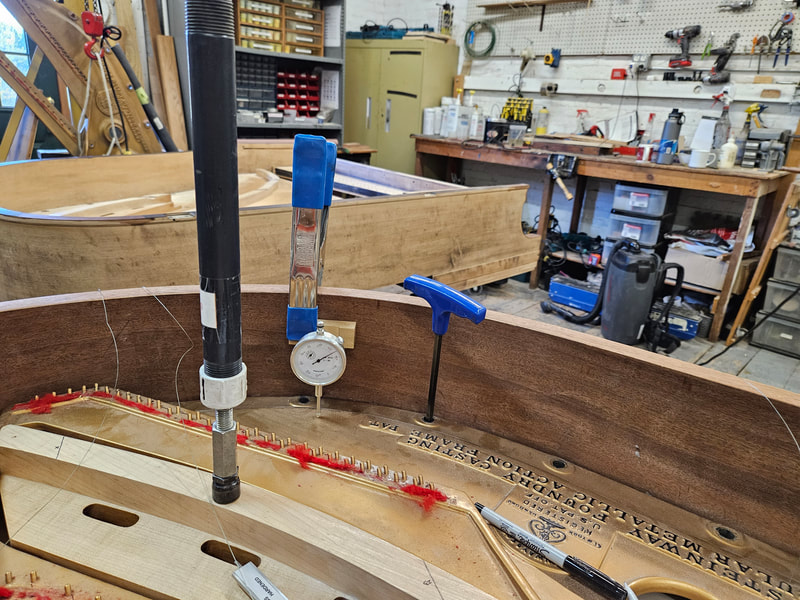

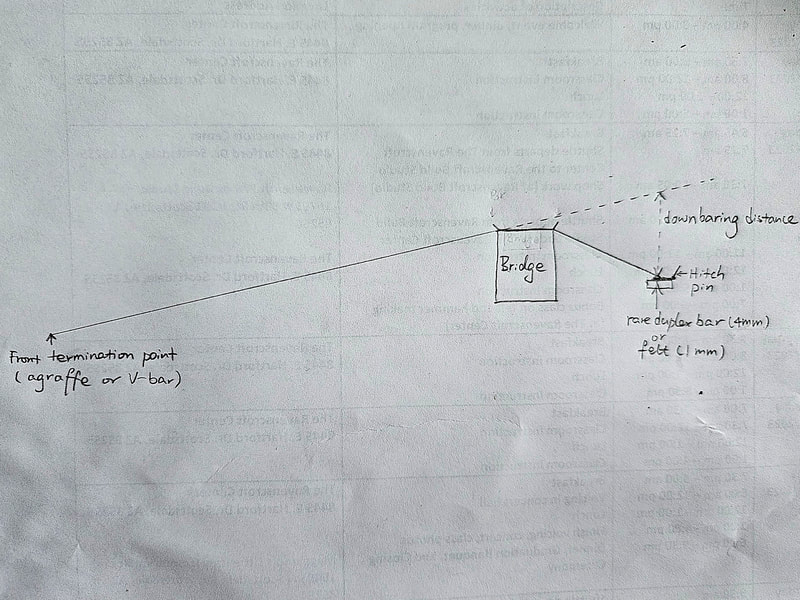

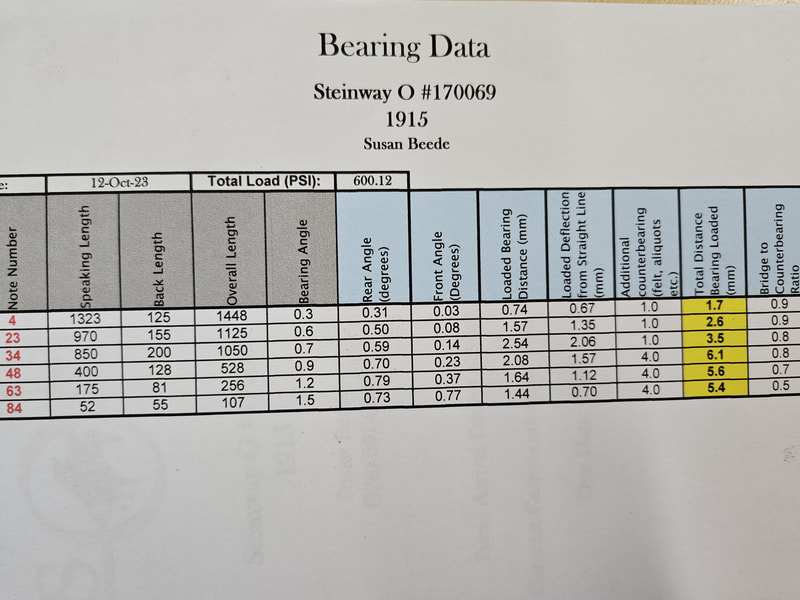

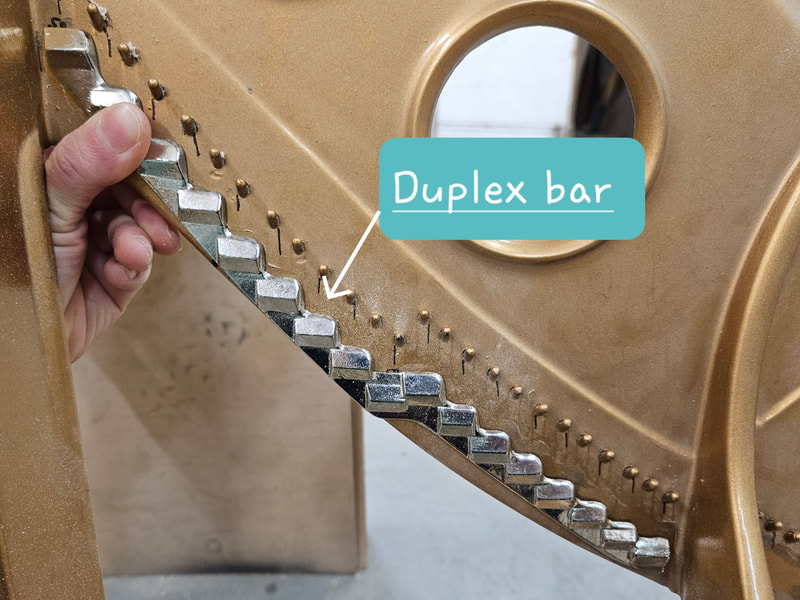

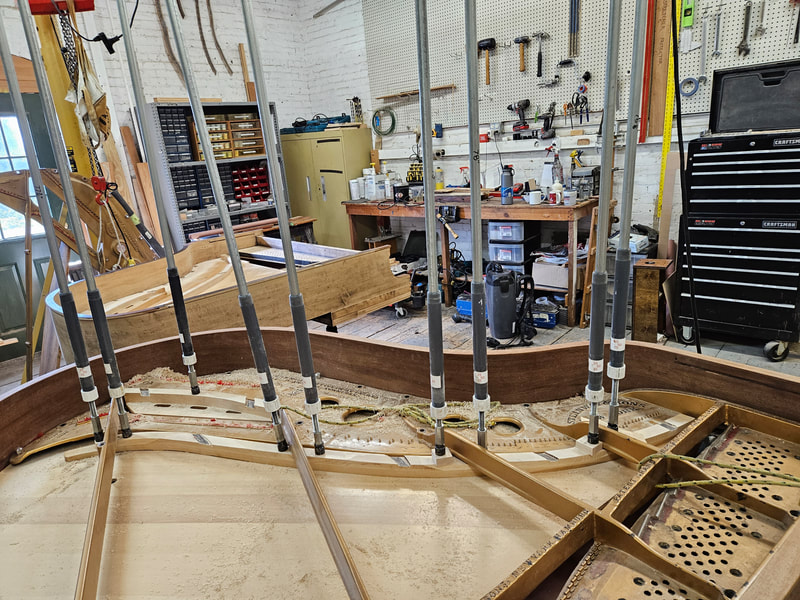

This is the first time setting downbaring on a whole piano after graduation from North Bennet Street School, seven years ago. While doing this, lots of old memories came back. Where has Mr. David Betts gone? Must be somewhere he can enjoy fishing, golf, fixing stuff, eating carrot cakes, have 6 things of butter with one corn muffin, etc. The procedure is instructed by our shop owner Mr. Jude Reveley. I had doubts during this practice. At least it is documented for friends and myself. On each section between struts, there will be one sample note on bridge grinded to ideal height. Then the plate can be taken off and whole bridge planed to height. First, load soundboard with go-bars to 600 pounds, 50LB on bass bridge, 550LB on treble bridge. The go bars must clear sample notes area and router space around it, each note is in the center between struts. Under each perimeter bolt hole, there is WNG perimeter bolt base (or lag screw) which can be turned up and down to adjust plate height. Turn up one bolt at the tail of the piano to the original plate height measured before rebuilding process. The height is from top of plate to top of rim. Check that there is still material to grind down on bridges. Lower the bolt/plate if necessary. Now turn up all bolt bases. Clamp pressure sensor next to the bolt being turned, bottom of sensor pressing on plate surface. Turn bolt base up until the sensor needle starts moving, then back down to just before the sensor needle moves. Do this on every bolt base. For the final pass, tab on plate right above bolt bass, turn it up till no knocking sound is present. This means the bolt surface is solid against plate bottom. Install 3 or 4 cap bolts around the perimeter to fasten plate (see picture on the right). The diagram shows exaggerated journey of one string. The dotted vertical line on the far right is what we are measuring - the downbaring distance. The shop owner calculated downbaring for this piano, which I'm still trying to learn. The numbers in yellow box on bottom left picture is the ideal downbaring distance. Thread strings through agraffes or go under v-bars in front of speaking length, check that it is at the correct location of sample notes from tuning pin hole or agraffe all the way to hitch pin. Pull it over the bridge, and touch down at hitch pin. Above the touchdown point where string touches rare counter baring (duplex bar or felt), press string down with bottom of micrometer till string touches front edge of bridge. Read the measurement. Keep pressing string down with micrometer. When string touches back of bridge, the height measured here shall be greater than 4mm if counter baring is rare duplex bar or greater than 1mm if counter baring is just felt. Use a router to grind down string passage at sample note, a little at a time till the ideal downbaring distance is achieved. It is better to leave bridge a little higher, say 0.5-1mm, to give it room for the final milling when the whole bridge is planed down to match and connect the ideal height at sample notes. Cover the finished area with pencil mark so I, or boss and colleagues, know no more grinding is needed. The left picture shows what's involved during this process. A small router works best here. Sometimes the front or back of bridge needs to be grinded more. A narrow sanding block is used to do the job. Always work a little, check, work more, check again, etc. When all samples are done, give it a final check before removing go-bars and plate. Now the bridge can be planed down to connect the height between samples.

This documentation is still immature, picture wise and word wise. Mr. Betts must be shaking his head. But I'm very grateful that our boss can provide this opportunity for his employee to practice and trust her on this. Do better next time! Hopefully... Comments are closed.

|

Archives

May 2024

|