|

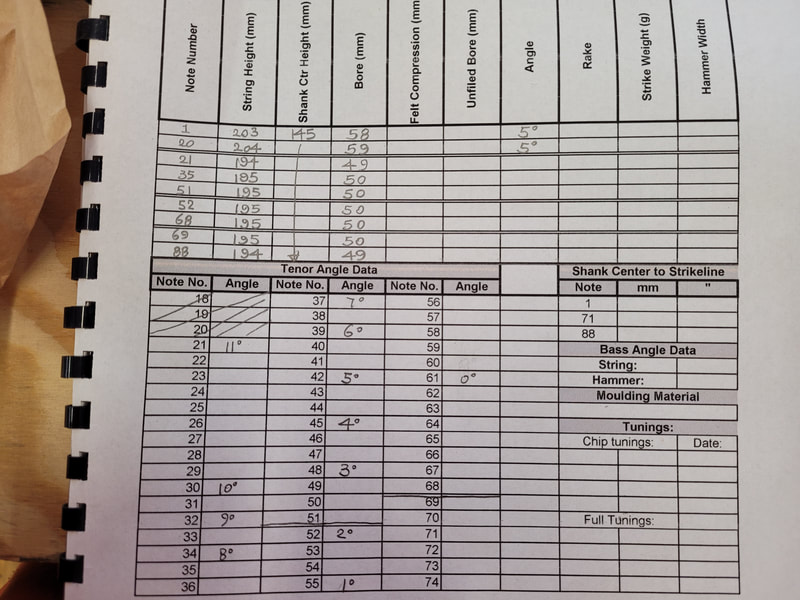

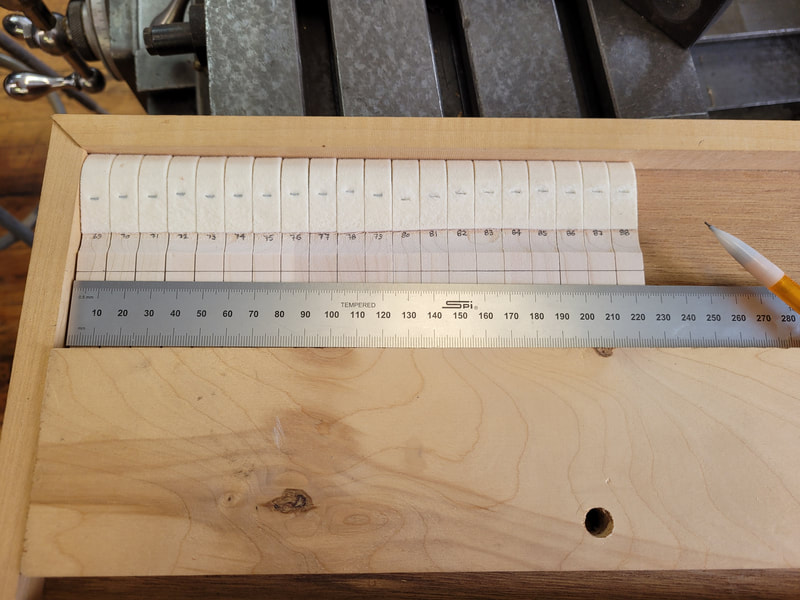

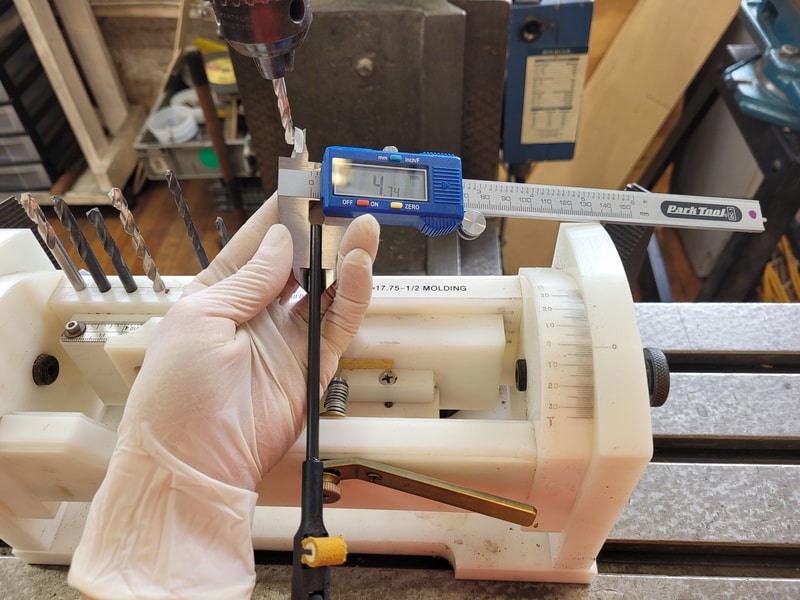

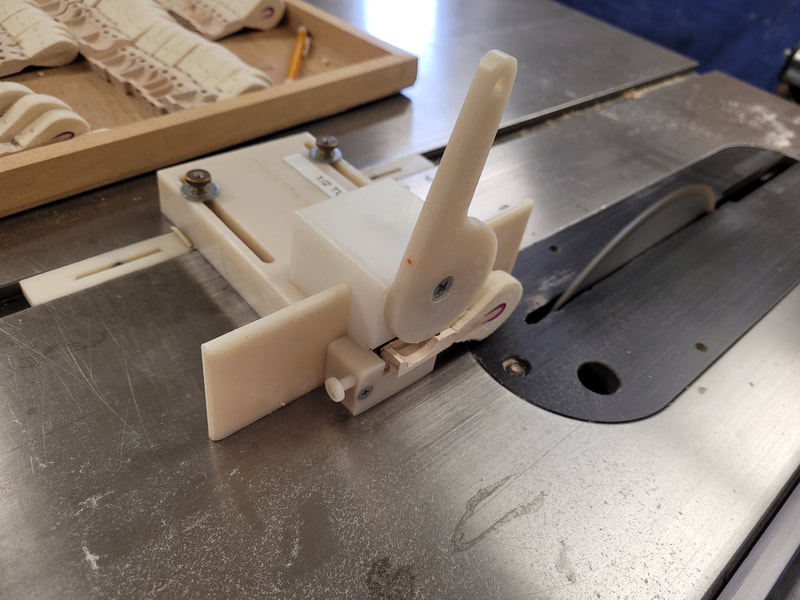

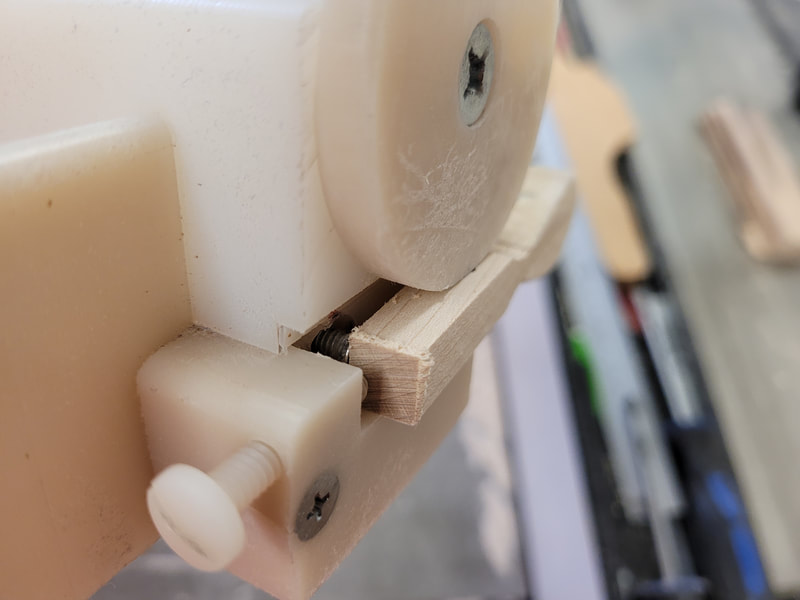

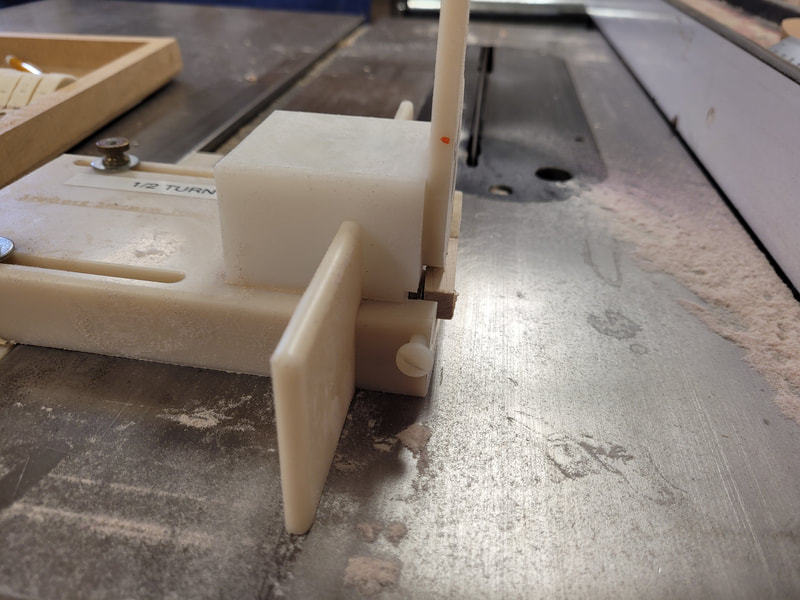

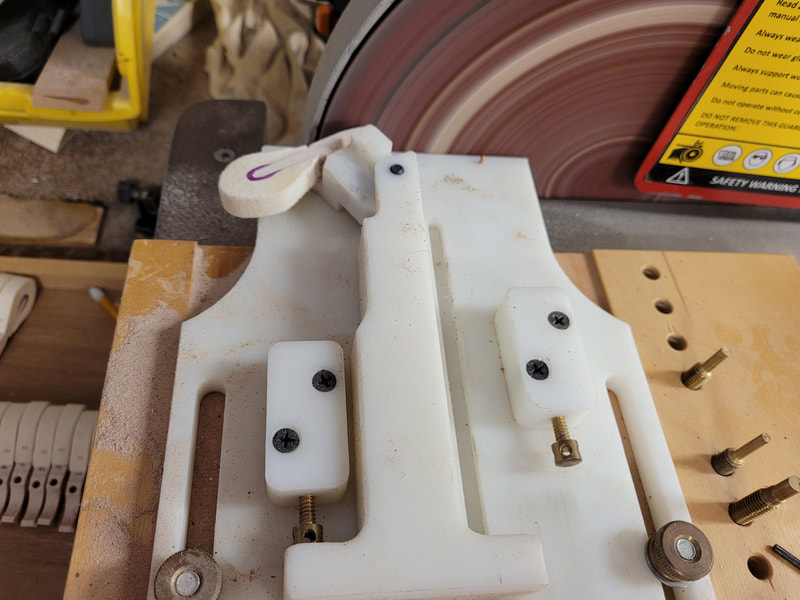

Data needed before opening hammer package: (1) String height at end of each section plus mid note at tenor section since this section is very long. The tenor section on this Mason is from note 21 to note 51. String height at note 35 is also recorded. (2) String angle along hammer strike line. Hammers will be drilled at an angle so the hammer top surface is parallel to the strings. (3) Hammer flange center pin height. Hammer bore = String height - Flange center pin height Fill out data sheet and double check that information and calculation is correct. Open hammer package carefully, organize hammers into each section, take out spare hammers from each section just in case someone is messed up here and there. Number all hammers. On jig, mark boring point/where to drill for hammer shanks on section end hammers. Connect the two marks with a ruler. Measure hammer shank thickness and pick the right drill bit. Drill/bore on marked lines. Keep data sheet on hand, rotate jig with the changing string angle documented. From center of drilled hole to tail of hammer, it shall be 1". The hammers are so long. They are cut close to 1" on bandsaw, then tailored to 1" exact on WNG jig and sanding disk. Without pre-cut on bandsaw, the sanding disk will be worn out too quickly. This coving jig is homemade by shop owner. The size of forstner bit is 7/8". Note that the hammer is not milled through. It is for easy grabbing and helps identify which hammer hasn't been worked on. Also, each time when coving off all wood or coving through, the big jumps a little. This can make small movement, big enough to make the work inconsistent. On the Spurlock hammer tapering jig, turn screw out 2.5 full turns to push hammer tail out to be milled off. Run one side of each hammer through table saw. If using SawStop, make sure the protection function is turned off. There are staples in each hammer which will trigger the machine to "stopping the spinning blade". So be very very very careful handling jigs and hammers. No music, podcast, nor any destructions here. The left picture shows one side tapered. Remember the un-milled-through coving process? It tells the worker that the bass side of hammers haven't been worked on. The un-milled-through part is easier to grab, too. Turn the push screw 2.5 turn out again to push the hammer tail out further, then mill the other side of hammers. The picture on the right shows hammers tapered on both sides. On WNG jig, taper each hammer tail on spinning sanding disk. The taper here is about 1cm long from tail end. Make sure the jig is placed to the edge of sanding disk so hammer felt is not affected by accident. Left picture shows comparison with the un-bored spare hammer. The hammers are ready to be hung on shanks now. The day ends here, too. Going home ^ ^.

Comments are closed.

|

Archives

May 2024

|